Fb ORDER PICKING HUBS.

For Startups and large enterprises.

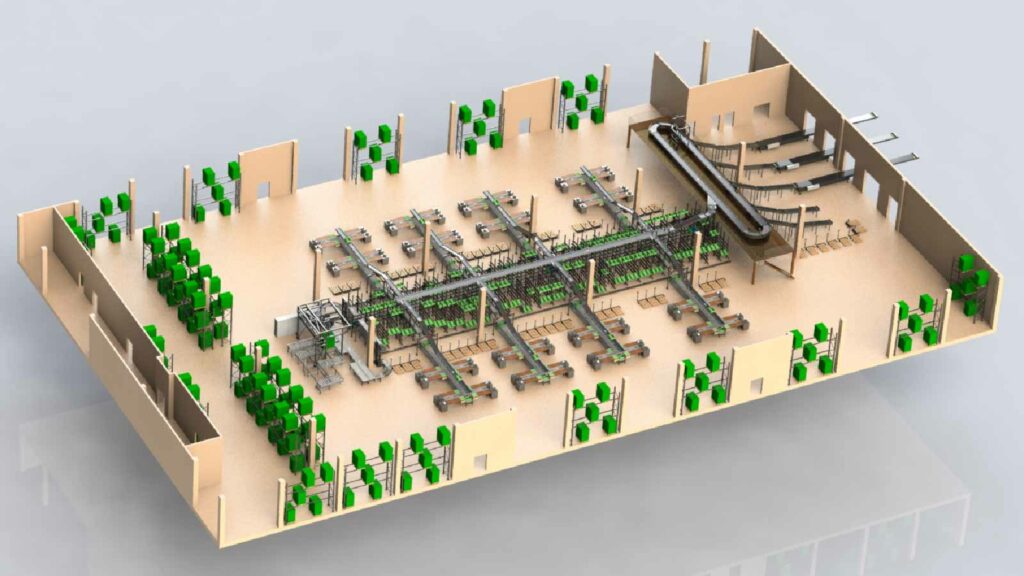

Unique warehouse logistics complete solutions, from de/palletising to order picking, packing and shipment. Your throughput is maximised cost-effectively and quickly with the Order Picking Hubs from Fb Industry Automation.

Flexible scalability of the Fb Order Picking Hubs.

The smart and simple concept of Fb Order Picking Hubs grows flexibly with your requirements. One Single Hub can easily serve up to six order picking stations.

In-house warehouse management software for simple operation.

The in-house warehouse management software Fb Stash ensures simple operation with pick-to-light and short training times for new employees. Moreover, the intuitive interface is available in several languages.

Short order picking routes and low space requirements.

The individual intralogistics steps are intelligently connected to one another. This shortens the order picking routes and reduces the space requirements. The hubs individually adapt to your needs.

“I’m still impressed by the performance and flexibility we’re able to achieve with the Order Picking Hubs from Fb Industry Automation. We were able to start with a small-scale solution, and now operate 4 order picking areas with 16 packing stations so that we can also serve peak times with 6.000 parcels per day. Our requirements were perfectly met in a very small space.”

RALF-PETER HARTMANN | Site Manager Shipping at RINGANA Munich

“I’m still impressed by the performance and flexibility we’re able to achieve with the Order Picking Hubs from Fb Industry Automation. We were able to start with a small-scale solution, and now operate 4 order picking areas with 16 packing stations so that we can also serve peak times with 6.000 parcels per day. Our requirements were perfectly met in a very small space.”

RALF-PETER HARTMANN | Site Manager Shipping at RINGANA Munich

DE/PALLETISING – STORAGE – ORDER PICKING – PACKING – SHIPMENT.

Up to 60% of warehouse operating costs are incurred during order picking and palletising of the goods. Fb Industry Automation offers a unique complete solution for all storage logistics steps in a single system. Depending on the scope and needs, we adapt the degree of automation and the size to suit your requirements. Perfect for everything from startups to large enterprises.

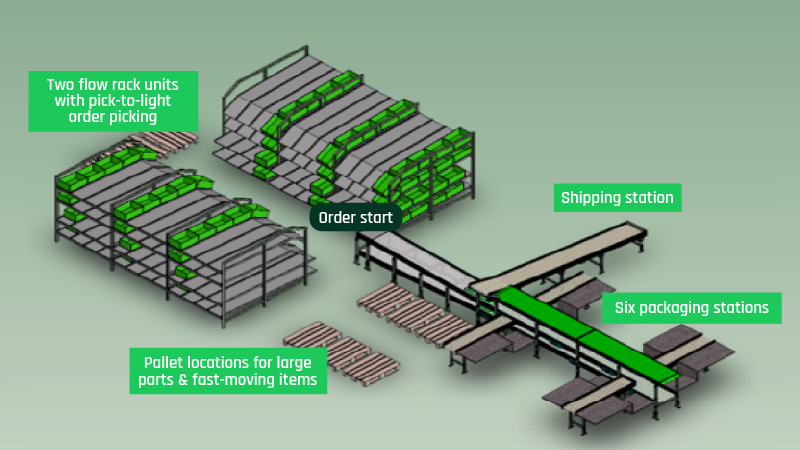

Fb SINGLE HUB WITH ≤6 ORDER PICKING AREAS.

You can quickly and cost-effectively serve up to six packing areas with an Fb Single Hub. The mirrored rack rows reduce order picking distances and time requirements. Here, the pick-to-light system is essential for fast and safe order-related picking by employees. The error rate is also reduced to a minimum. Fast movers and large parts are provided on pallets.

This smart setup delivers cost-effective and quick resource savings and maximum performance to your intralogistics. Perfect for the first automation step.

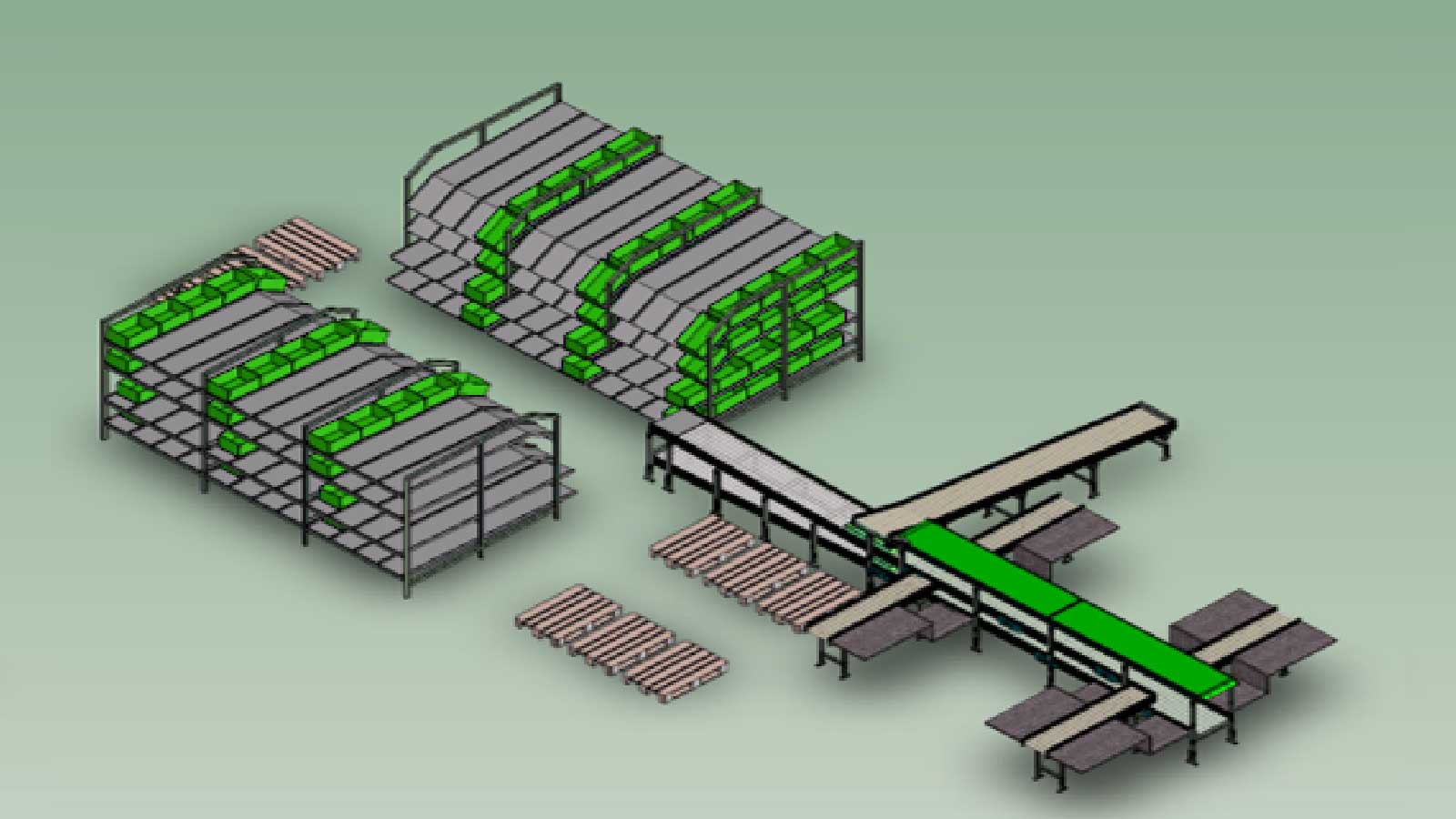

Fb DOUBLE HUB FOR ≤16 PACKING STATIONS.

With the intelligent design the Fb Single Hub can be extended individually over time. An Fb Double Hub consists of an Fb Single Hub set up in mirrored form. This allows shipping to be consolidated in one place so that it efficiently uses space and resources. Depending on requirements, an Fb Double Hub has twelve to sixteen packing stations. In the centre of the rack cells two order pickers process orders using a pick-to-light system.

Processed containers are transported to packing stations using a conveyor belt. The packages are then automatically transported to the central shipping station.

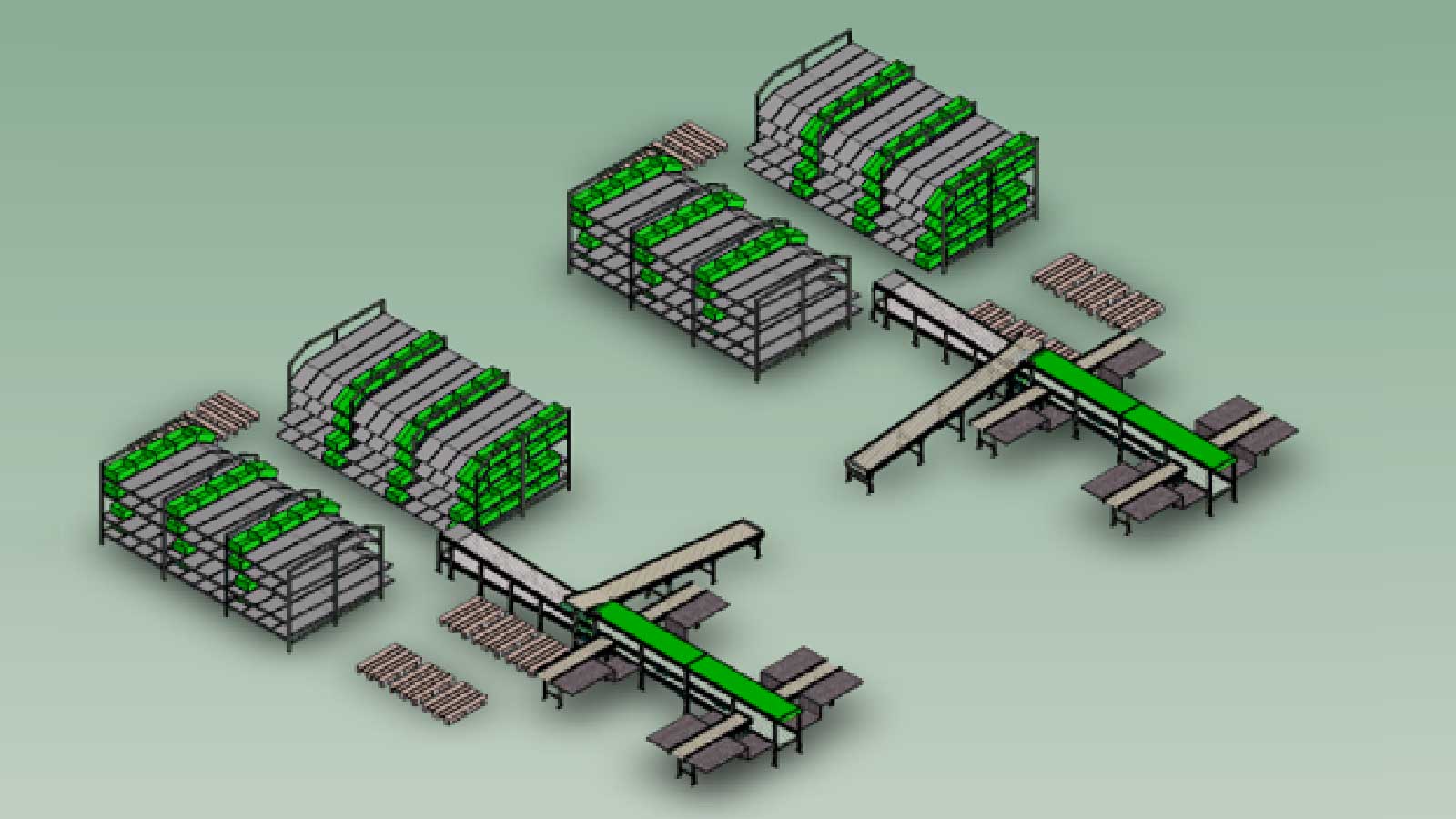

Fb MULTI HUB FOR FLEXIBLE GROWTH OVER TIME.

Multiple Fb Double Hubs can be connected to each other using overhead conveyor technology. The picked orders and packages are automatically transported to one shipping station, or more if required. For example, one shipping station can be established for each logistics company, which increases efficiency.

The transport between the individual work steps is completely automated.

Maximum system performance thanks to intelligent solution modules. Your Fb Order Picking Hub grows with you. Minimal risk and use of resources for maximum performance.

Fb MASTER HUB FOR FULL AUTOMATION.

Extensive automation requirements. The internal material flows are designed efficiently and ergonomically for maximum performance. The Fb Master Hub becomes the heart of your intralogistics.

Individually designed performance-oriented pre-zone conveyor technology takes over goods receipt. De/palletisation is performed by pallet conveyor technology. The integrated buffer loop ensures decoupling of the manual feeding station and the fully automated depalletising portal. The portal takes the individual containers from the pallet and transfers them to the container conveyor technology.

The individual containers are allocated to the matching racking levels by a container lift and thus fed to the automated Fb Sorter Shuttle System. The Sorter Shuttle distributes the containers, with the items to be packed, to the flow racks.

The racks automatically serve the order picking areas, in this example, eight workstations are served simultaneously. Customer orders are processed using a software-controlled pick-to-light system. To do this, an order picking employee scans an empty container that is already assigned to a customer order. After scanning, the order picker is visually shown the items that need to be picked, as well as the number of each item, on light panels on the flow rack. This allows the right number of products to be picked easily and quickly. A button under the container is used to confirm the removal. The software-guided order picking process with Fb Stash reduces the error rate to a minimum and maximises order picking performance.

Processed order containers are automatically transferred to one of the eight associated packing workstations via the outgoing container conveyor technology. There, the customer orders are packed into boxes, which, in the last step of the process, are transferred to outgoing goods by the outgoing conveyor technology.

All steps are controlled using the high-performance Fb Stash software. A 360+ complete solution from Fb Industry Automation for your storage logistics.