The heart of intralogistics

Fb STASH: INTELLIGENT SOFTWARE FOR YOUR WAREHOUSE.

CONTENT

01.

FROM COMPLEXITY TO CLARITY.

FROM PROCESSES COMES PERFORMANCE.

At first glance, everything seems fine in many companies. But on closer inspection, it becomes clear that something crucial is missing behind the scenes: clarity. control. transparency.

Key questions often remain unanswered. Where exactly is a specific item located? Why is order picking delayed? And how can new systems be integrated into existing structures without having to completely rethink the entire warehouse concept?

The cause does not lie in technological progress itself—but rather in the fact that this progress is rarely considered holistically. Many warehouses operate with legacy system landscapes where isolated solutions exist side by side: ERP, scanners, conveyor technology, automated vehicles—and in between, a multitude of manually maintained processes, lists, and handover gaps.

Additionally, many of the warehouse management systems (WMS) in use are no longer up to date. They originate from a time when processes were more static and requirements more manageable. Today, they often feel like foreign bodies in the dynamic warehouse environment: sluggish, inflexible, technically outdated, or simply too complex for operational reality. Instead of simplifying workflows, new obstacles arise—especially when companies grow, integrate new technology, or want to adapt processes.

What should actually control, only manages.

And what was intended as digitalization often ends up as an opaque black box.

The result is a growing loss of control—and the impression that, despite modern technology, no one really knows what is happening in the warehouse.

THIS IS WHAT Fb STASH CAN DO IN YOUR WAREHOUSE.

And much more.

Warehouse Location Management

Function:

– Intelligent storage according to rules (ABC, FIFO, zone logic, etc.)

– Management of fixed and dynamic storage locations

– Automatic location suggestions or assignments

Benefits:

→ Optimal space utilization & more efficient routes.

Goods Receipt & Posting

Function:

– Receipt and posting of incoming goods

– Assignment to orders, suppliers & storage locations

– Inspection for discrepancies

Benefits:

→ Faster throughput and accurate system postings.

Order Management / Inventory Transfer

Function:

– Control & prioritization of customer orders

– Linking order data with warehouse processes

– Transfer to other systems (ERP, TMS, etc.)

Benefits:

→ Holistic view of order and inventory.

Tracking

Function:

– Real-time tracking of goods and storage locations

– Transparent localization within the warehouse (e.g., via scanners, AGVs, RBG)

– Visualization of movements & inventory

Benefits:

→ Warehouse management always knows where items, load carriers, or orders are located.

Quality Control & Inspection

Function:

– Incoming goods inspection (e.g., quantities, quality, damages)

– Digitally map quality assurance processes

– Documentation & approval processes

Benefits:

→ Minimization of errors & returns, high process reliability.

Order Picking & Material Provisioning

Function:

– Control of manual and automated order picking

– Multi-order, batch, or single order picking

– Pick-by-light, mobile data terminal integration, digital packing lists

Benefits:

→ Faster order processing, fewer picking errors.

Shipping & Handover

Function:

– Shipping preparation including labeling, packaging, and route assignment

– Handover to carrier or end customer

– Shipment tracking & status notifications

Benefits:

→ Smooth shipping, full traceability.

Shipping Logistics / Distribution

Function:

– Integration with external logistics systems and carriers

– Handling of cross-docking, returns, loading

– Export / customs documentation (if applicable)

Benefits:

→ Transparent and traceable delivery processes.

Exactly here is where Fb Stash comes in: Our software was developed to finally create connections—between systems, devices, people, and processes.

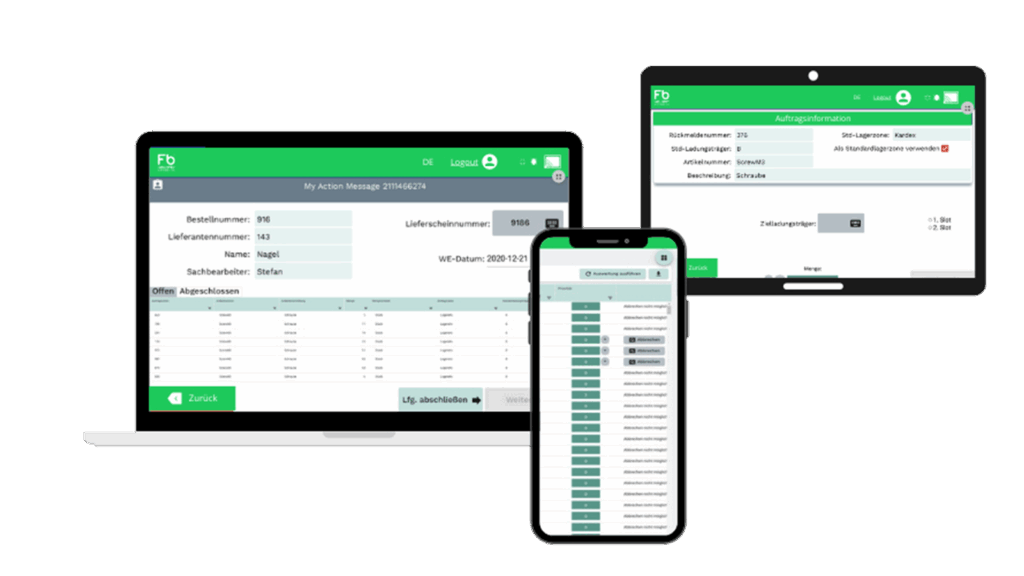

Fb Stash does not see your warehouse as a static place, but as a dynamic network. That’s why the solution is modular, intuitive to use, and fully integrable—from the ERP level down to individual scanners or automated guided vehicles (AGVs). This means you don’t have to start from scratch. You can work with what you already have—just smarter and more connected.

What was once considered a complex challenge—such as integrating automated warehouse technology, controlling order picking processes in real time, or seamless communication between goods receipt and shipping—becomes a central strength with Fb Stash. Because the software not only maps what is happening, it actively controls, detects bottlenecks early, gives you back control—and creates transparency that enables decision-making.

In short: Fb Stash is not just another WMS. It is the operational operating system for your intralogistics.

03.

WHAT Fb STASH DELIVERS.

There are many digital warehouse processes—but few systems truly map and control them end-to-end. Fb Stash does exactly that: it takes over not just management, but the operational control of your entire intralogistics—from goods receipt and storage to order picking and shipping preparation.

The software tracks every movement in the warehouse in real time. Items are not only posted but intelligently placed—based on ABC analysis, FIFO strategies, or individual rules. Feedback and transfers happen digitally, seamlessly, and transparently. Order picking becomes a planned process instead of a constant reaction to bottlenecks. And shipping? It is carried out in a structured manner—with clearly defined handover points and automatic tracking.

It’s not just about process efficiency, but about operational clarity. Warehouse managers and those responsible always know what’s happening—and where there might be bottlenecks. They see which orders are in progress, how many resources are tied up, and where action is needed. Instead of waiting for data, you act in real time.

Another advantage: complete technical openness. Fb Stash speaks the language of your existing systems—whether SAP, Navision, proALPHA, or another ERP solution. Conveyor systems, automated guided vehicles (AGVs), mobile data entry devices, or pick-by-light systems can also be integrated seamlessly. And if a new interface is needed? It is simply built—without elaborate large-scale IT projects:

The system grows with your requirements, not against them. Whether you start with a basic project or want to cover multiple warehouse areas right away—Fb Stash remains flexible, modular, and scalable. Throughout, you never lose control over your data and processes.

And that’s exactly the difference: while many systems rely on maximum complexity, Fb Stash brings structure, clarity, and operational confidence—from day one.

04.

Fb STASH SEAMLESSLY INTEGRATED.

In modern warehouse and logistics processes, software is only powerful when it thinks in a connected way. This is exactly where Fb STASH comes in: as a central integration platform, the solution seamlessly, flexibly, and future-proof connects your existing IT with physical warehouse technology.

Whether ERP system, conveyor line, stacker crane, AGV, scanner, or pick-by-light: Fb STASH integrates all these systems into a unified, seamlessly controlled environment. The result is a complete operational picture—in real time and without media disruptions.

Thanks to modular architecture and open interfaces (e.g., REST, ActiveMQ, MQTT, OPC UA), new systems can be connected at any time—without costly modifications or lengthy IT projects. This makes Fb STASH especially suitable for retrofit projects and hybrid warehouse environments.

ERP-Systeme

SAP, proALPHA, Microsoft Navision, Sage, Infor u. v. m. (per REST-API, XML, etc.)

Stacker crane

Shuttles

Pick-to-light

Order picking

Scanner

AGV's

CASE STUDY

RINGANA IS CONVINCED OF Fb STASH.

From 6,000 packages per week to 6,000 packages per day — how is that possible? With our flexible Fb Order Picking solutions that grow with your requirements.

LET’S GET THINGS MOVING.

As a reliable partner, we will guide you into the world of automation and far beyond. With unique all-in-one systems and customised solutions, we shape your future together.