WAREHOUSE OPTIMIZATION FOR THE PHARMA-, COSMETIK- & HEALTHCARE INDUSTRIES

Our Tips for your warehouse

NEWS / MEDIA

HOW TO OPTIMIZE

YOUR PHARMACEUTICAL-, COSMETIK & HEALTHCARE-WAREHOUSE.

In the fast-paced world of pharmaceuticals, cosmetics, and healthcare, efficient inventory management plays a crucial role in a company’s success. The demands on inventory solutions in these industries are high: they must not only be efficient and flexible but also meet the highest standards of safety, hygiene, and traceability. In this blog post, we will explore the key strategies and innovative solutions that contribute to optimizing your inventory in the fields of cosmetics, pharmaceuticals, and healthcare.

CHALLENGES IN THE INDUSTRY

DOES THIS SOUND FAMILIAR TO YOU?

Pharmaceutical products often require strict temperature controls and special storage conditions to ensure their efficacy and safety. Cosmetics need to be protected from contamination, and healthcare products are frequently subject to stringent regulatory requirements. Additionally, batch traceability and compliance with traceability regulations are crucial.

Imagine how sensitive pharmaceutical products are. A slight temperature variation can affect their efficacy. It’s like guarding a treasure—except this treasure can save lives. Maintaining the correct temperature is crucial to ensure the integrity and effectiveness of the products.

In the cosmetics and healthcare industries, absolute purity is a must. You need to ensure that every product leaving the warehouse is free from contaminants. Imagine producing an exquisite cream or a life-saving medication—each product must be flawless. This requires stringent hygiene measures and continuous monitoring.

The thought that a mistake could lead to contamination is frightening. Protection and security are not just buzzwords but essential components of the storage process. Each product must be stored safely and intact, as if it were a precious gem.

In times of recalls and stringent regulations, batch traceability is of utmost importance. It’s like documenting the entire lifecycle of a product—from production to delivery. Every movement and every change must be meticulously recorded to enable quick and efficient action in case of an emergency.

Space in warehouses is often limited, and optimal space utilization is crucial. Imagine solving a puzzle where every space must be used perfectly. Every shelf and storage location needs to be arranged to maximize the available space without compromising efficiency

The pharmaceutical, cosmetic, and healthcare industries are heavily regulated. Compliance with these regulations is not only a legal obligation but also a testament to customer trust. One must stay up-to-date and ensure that all processes and products meet the highest standards

TIPS FOR OPTIMIZING YOUR WAREHOUSE

SMART 360+ COMPLETE SOLUTIONS

FOR YOUR INTRALOGISTICS.

To meet the challenges of your industry, an increasing number of companies are relying on innovative technologies and customized 360+ comprehensive solutions for inventory optimization. Here are some of the key strategies:

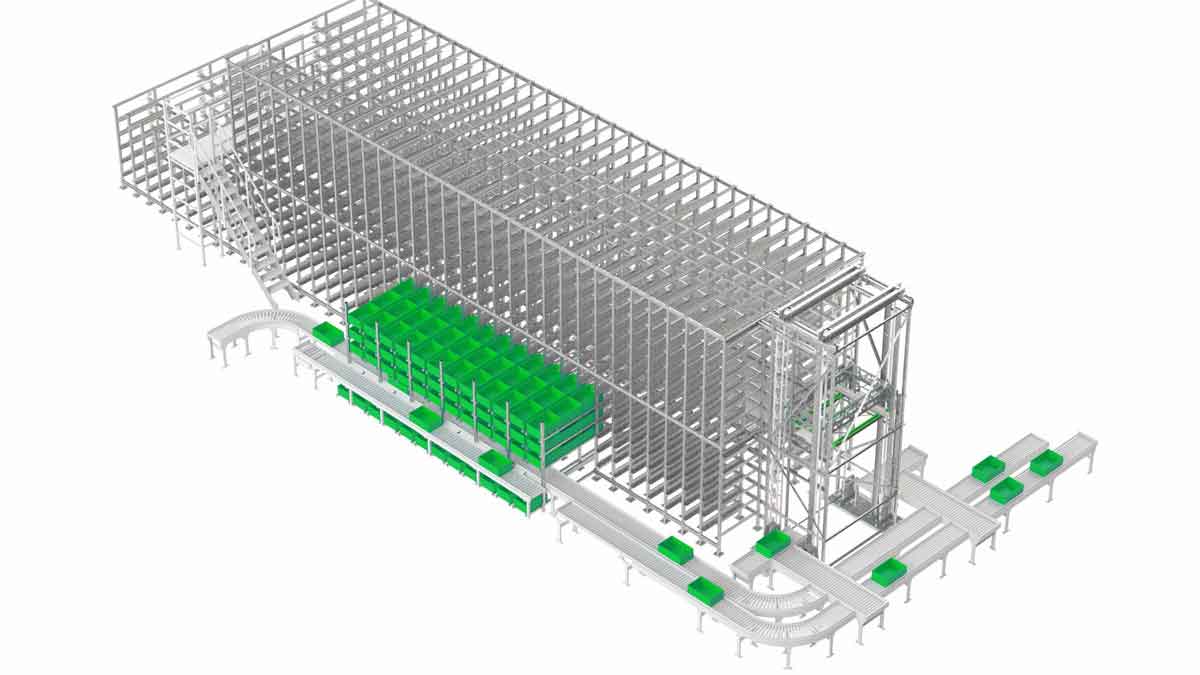

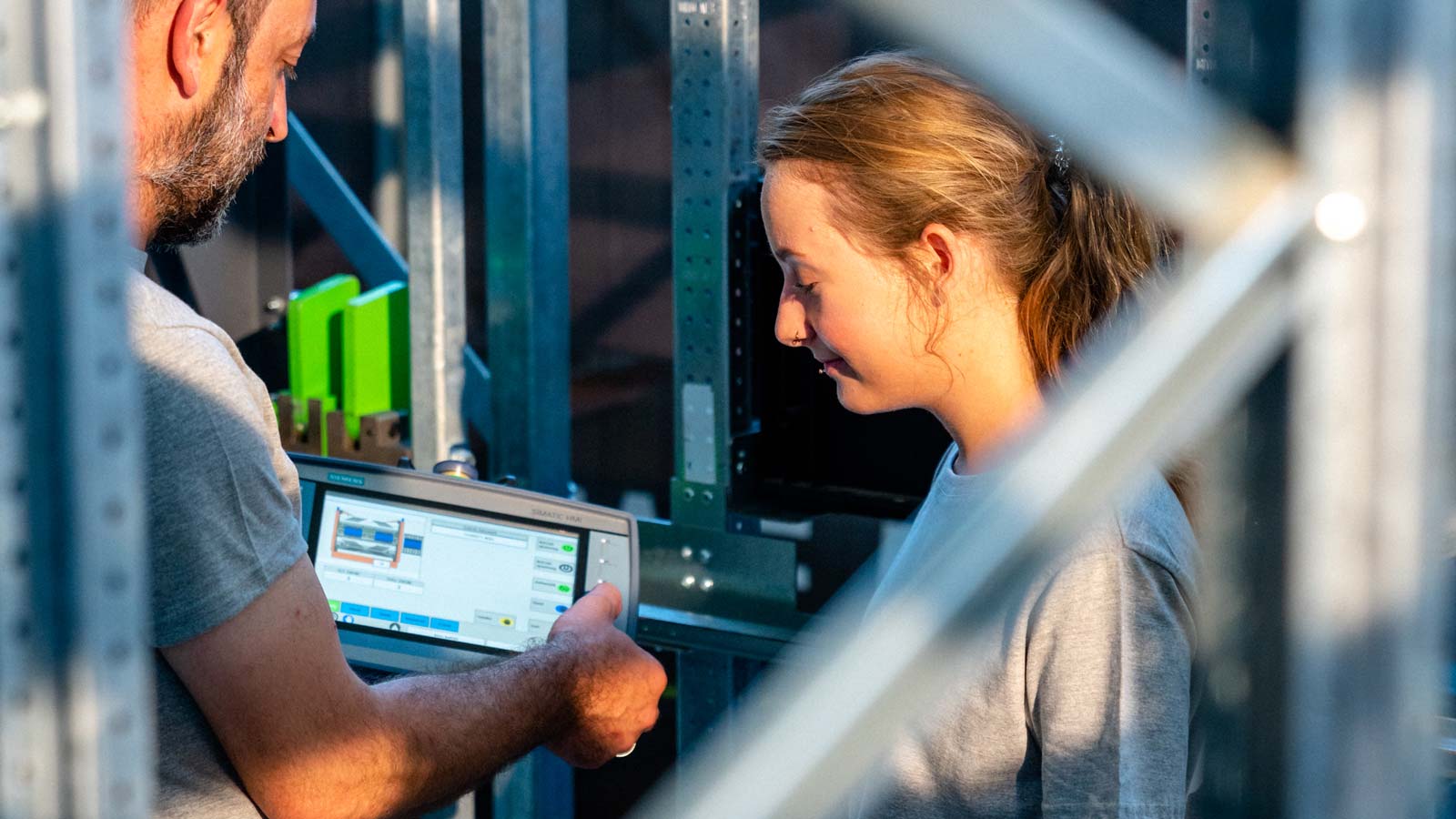

Automated warehousing and picking systems are revolutionizing inventory management in the pharmaceutical, cosmetic, and healthcare industries. By utilizing advanced warehouse management systems (WMS), such as our software Fb Stash, companies can streamline their processes. These systems enable precise and fast picking, reduce errors, and improve inventory accuracy.

One example is the use of Pick-to-Light technology, where light signals guide employees to the correct storage location. This technology significantly enhances picking accuracy and speed while reducing error rates.

For many pharmaceutical products, strict temperature monitoring is essential. Modern warehouse systems offer integrated solutions for climate control and real-time monitoring of storage temperatures. This ensures that products are always stored under optimal conditions and their quality is maintained.

By using sensors and automated notification systems, companies can immediately respond to deviations and thus avoid potential damage. This technology is especially important for products sensitive to temperature fluctuations, such as vaccines and biopharmaceuticals.

Maintaining high hygiene standards is crucial in the cosmetics and healthcare industries. Modern warehouse solutions therefore include stringent hygiene measures and contamination control technologies. This includes specialized shelving and surfaces that are easy to clean, as well as systems for monitoring air quality in the warehouse.

An innovative approach is the use of UV-C disinfection robots, which regularly disinfect warehouse areas and thus minimize the risk of contamination. This technology ensures a clean and safe storage environment and protects products from contamination.

Traceability of batches and compliance with regulatory requirements are essential for companies in the pharmaceutical, cosmetic, and healthcare sectors. Modern warehouse management systems offer comprehensive traceability solutions by documenting every movement and location of a product within the warehouse.

By using barcode and RFID technology, companies can monitor the entire product lifecycle and ensure that all regulations are met. These systems also enable quick and efficient action in the event of recalls by accurately identifying which batches are affected.

Sustainability is playing an increasingly important role in warehousing. Companies are increasingly adopting energy-efficient solutions and sustainable practices (retrofit) to improve their environmental footprint. This includes the use of energy-efficient lighting systems, automated climate controls, and sustainable packaging materials.

By implementing energy-efficient warehouse solutions, companies can not only reduce their operating costs but also make a positive contribution to environmental protection. Sustainability becomes an important competitive factor and enhances a company’s image.

01

AUTOMATION!

Automated warehousing and picking systems are revolutionizing inventory management in the pharmaceutical, cosmetic, and healthcare industries. By utilizing advanced warehouse management systems (WMS), such as our software Fb Stash, companies can streamline their processes. These systems enable precise and fast picking, reduce errors, and improve inventory accuracy.

One example is the use of Pick-to-Light technology, where light signals guide employees to the correct storage location. This technology significantly enhances picking accuracy and speed while reducing error rates.

02

SIMPLIFY YOUR TEMPERATURE CONTROLS!

For many pharmaceutical products, strict temperature monitoring is essential. Modern warehouse systems offer integrated solutions for climate control and real-time monitoring of storage temperatures. This ensures that products are always stored under optimal conditions and their quality is maintained.

By using sensors and automated notification systems, companies can immediately respond to deviations and thus avoid potential damage. This technology is especially important for products sensitive to temperature fluctuations, such as vaccines and biopharmaceuticals.

03

SIMPLIFY YOUR HYGIENE MEASURES!

Maintaining high hygiene standards is crucial in the cosmetics and healthcare industries. Modern warehouse solutions therefore include stringent hygiene measures and contamination control technologies. This includes specialized shelving and surfaces that are easy to clean, as well as systems for monitoring air quality in the warehouse.

An innovative approach is the use of UV-C disinfection robots, which regularly disinfect warehouse areas and thus minimize the risk of contamination. This technology ensures a clean and safe storage environment and protects products from contamination.

04

IMPROVE TRACEABILITY!

Traceability of batches and compliance with regulatory requirements are essential for companies in the pharmaceutical, cosmetic, and healthcare sectors. Modern warehouse management systems offer comprehensive traceability solutions by documenting every movement and location of a product within the warehouse.

By using barcode and RFID technology, companies can monitor the entire product lifecycle and ensure that all regulations are met. These systems also enable quick and efficient action in the event of recalls by accurately identifying which batches are affected.

05

MAKE YOUR INTRALOGISTICS GREENER!

Sustainability is playing an increasingly important role in warehousing. Companies are increasingly adopting energy-efficient solutions and sustainable practices (retrofit) to improve their environmental footprint. This includes the use of energy-efficient lighting systems, automated climate controls, and sustainable packaging materials.

By implementing energy-efficient warehouse solutions, companies can not only reduce their operating costs but also make a positive contribution to environmental protection. Sustainability becomes an important competitive factor and enhances a company’s image.

BENEFITS OF

WAREHOUSE OPTIMIZATION.

The introduction of new technologies and processes in your warehouse is a crucial step towards optimizing operations and increasing efficiency. A comprehensive evaluation approach includes various metrics that together provide a clear picture of performance improvements and cost savings.

INCREASE IN ORDER FULFILLMENT CAPACITY

A central goal of implementing new warehouse technologies is to increase order fulfillment capacity. This involves measuring how many orders can be processed per day. Accurately capturing this metric helps not only to evaluate the efficiency of warehouse operations but also to better manage capacity planning and future growth. Automated systems and modern software solutions can significantly boost throughput, positively impacting customer satisfaction and market position.

IMPROVEMENT OF PICKING ACCURACY AND SPEED

An efficient picking process not only reduces error margins but also optimizes throughput times. Technologies like Pick-to-Light systems can facilitate significant advancements in this area. In Pick-to-Light, a visual signal is activated to guide the picker to the correct items, minimizing sources of error and increasing picking speed. This technology enables employees to locate items quickly and accurately, improving both the efficiency and accuracy of the picking process.

OPTIMAL SPACE UTILIZATION

Effective utilization of warehouse space is another important aspect. Analyzing space utilization and storage capacity helps determine whether the available space is being used optimally or if there are unused capacities. Technological innovations such as dynamic shelving systems and optimized warehouse layout planning can help make better use of space and increase storage density. This can lead to reduced storage costs and better adaptation to the flow of goods.

COST SAVINGS

The implementation of new technologies should result in noticeable cost savings. It is important to calculate the impact of these new technologies on operating costs. This includes savings in labor, energy efficiency, and maintenance costs. A detailed cost-benefit analysis can demonstrate how quickly investments pay off and what financial benefits can be achieved. These savings are typically realized through process improvements and reductions in errors and delays.

CASE STUDY

OUR Fb SOLUTION FOR RINGANA.

From 6,000 packages per week to 6,000 packages per day – how is this possible? With our flexible Fb order picking solutions that grow with your requirements.

SOLUTIONS

MANY OPPORTUNITIES

FOR YOUR INTRALOGISTICS.

Optimizing inventory for the pharmaceutical, cosmetic, and healthcare industries requires innovative solutions and customized approaches to meet the high demands of these sectors. Automated systems, strict temperature and hygiene controls, comprehensive traceability, and sustainable practices are key factors that contribute to increased efficiency and safety in inventory management.

By implementing these technologies and strategies, you can not only enhance your operational efficiency but also ensure the quality and safety of your products. In an increasingly regulated and competitive industry, optimizing inventory processes is a crucial key to success. For more information on how your company can benefit from modern inventory solutions, please contact our expert team. We offer customized solutions tailored to your specific needs to help you optimize your inventory processes and achieve your business goals.

INITIAL-LOGISTICS AUTOMATION.

How to Successfully Transition from Manual Processes to Warehouse Automation.

The Fb Logistics team makes your first step towards warehouse logistics automation simple. We support you as a strategic partner from the initial potential analysis to the commissioning of your system and beyond.

INTRALOGISTICS-EXPANSION.

Flexible Automation for Your Existing Systems.

As your business success grows, so do the demands on the efficiency and speed of your internal warehouse processes, regardless of whether market conditions or your product variety change.

INTRALOGISTICS-RETROFIT.

Your Customized Modernization as a Facelift for Your Warehouse Technology.

Are you truly satisfied with your current warehouse processes? Do they meet all your requirements? Whether you want to completely replace your existing warehouse logistics system or just modernize parts of it, we will develop the ideal retrofit solution for you.

FURTHER CASES.

Hausbrot.at | Packing line | Fb Industry Automation

Hausbrot.at supplies kindergartens, businesses, and private households daily with fresh baked goods and other food products. However, with around 1,000 orders per day, the company reached the limits of its manual warehouse management. To meet the increasing demands, Hausbrot.at decided to undertake a comprehensive modernization of its intralogistics. In collaboration with Fb Industry Automation, a highly automated warehouse system was developed and implemented, which not only significantly increased efficiency but also minimized error rates and improved working conditions. Curious about how this project was realized? Discover all the details in our case study!

BIG Bundesimmobiliengesellschaft – library of the university Graz

During the realisation of the construction project “Renovation and extension” of the library of the Karl-Franzens University of Graz”, the section of the library built in the 1970s created an obstacle to this important urban development. The historic library building has been transformed over several construction phases from the original clarity of its symmetrical late-19th century layout to a complex conglomerate of different room sequences.

Library of the University Graz | Automated book conveyor system

The University of Graz (formerly Karl-Franzens University) is the largest university in Styria and the second oldest university in Austria after Vienna.

During the course of the construction project “Renovation and extension of the library of the Karl-Franzens University of Graz”, the construction of a new automated book conveyor system was also planned and implemented.