MAGNA IN GRAZ.

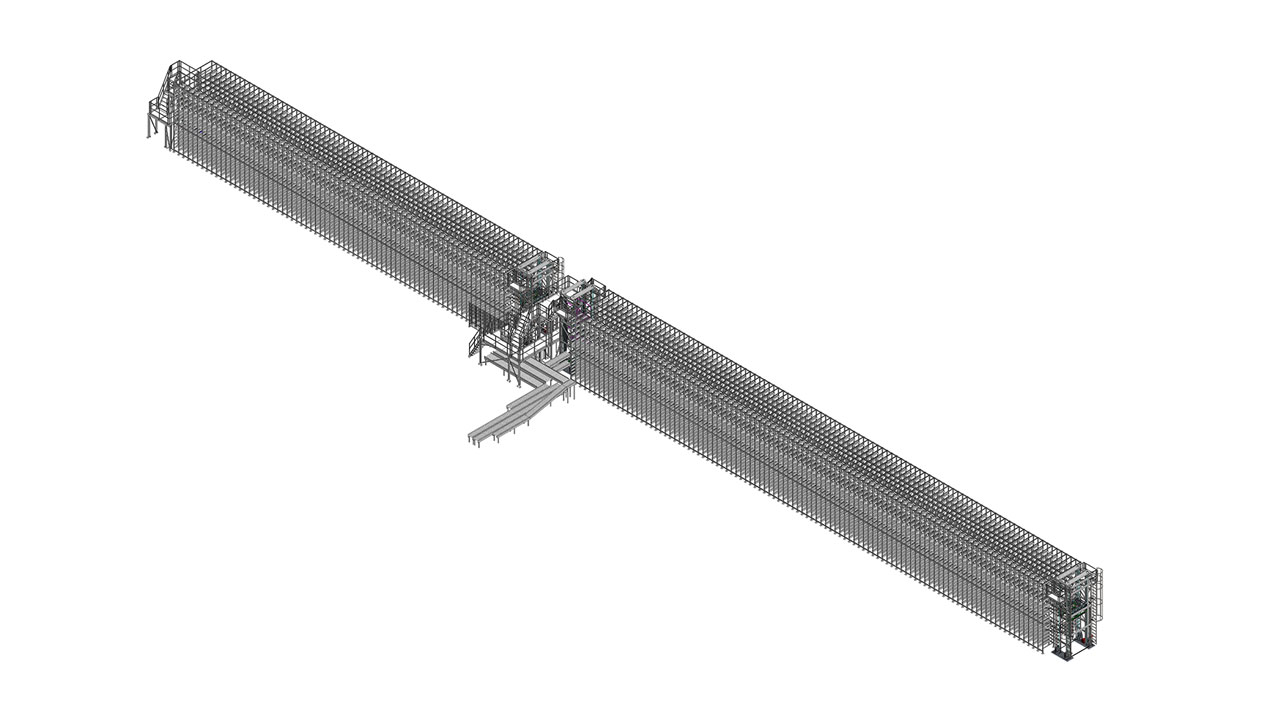

Tailor-made automatic small parts warehouse (AS/RS) for loads up to 120 kg and 19,000 storage spaces.

PROJECT

MAGNA STEYR – AUTOMATED SMALL PARTS WAREHOUSE.

More than 120 years of experience in automotive engineering and the company’s comprehensive range of services make Magna Steyr the world’s leading, brand-independent engineering and manufacturing partner for car manufacturers. As a contract manufacturer, Magna Steyr has so far produced more than 3.7 million vehicles, spread over 30 models.

- Automotive

- Graz, Austria

- Feb. 2020 - Feb. 2021

- Automated small parts warehouse (AS/RS) incl. workplace connectivity for 19,000 storage locations.

INITIAL SITUATION.

- 1999: Installation of a small parts warehouse with a storage and retrieval machine (SRM) and a small staging area for storage and retrieval, as well as an order picking and an inspection/defect line.

- 2016: Retrofit (=upgrade/modernisation) of the entire plant.

PROJECT REQUIREMENT & CUSTOMER EXPECTATIONS.

- Increase in capacity and greater number of storage locations for production warehouse logistics.

- Higher number of retrievals and deposits per hour.

- More efficient design of goods availability in terms of throughput.

- Improvement of the system reliability and maximum fail-safety.

- Continued use of all existing container types.

- Manual access options and appropriate distribution of goods for consistent item availability, even in the event of a plant system failure.

- Implementation and commissioning of the new system as well as relocation of the goods without interfering with the running 2-shift line operation.

CUSTOMER BENEFITS OF THE 360+ Fb COMPLETE SOLUTION. .

- The Fb Compact Warehouse,as a flexibly expandable automatic small parts warehouse (AS/RS).

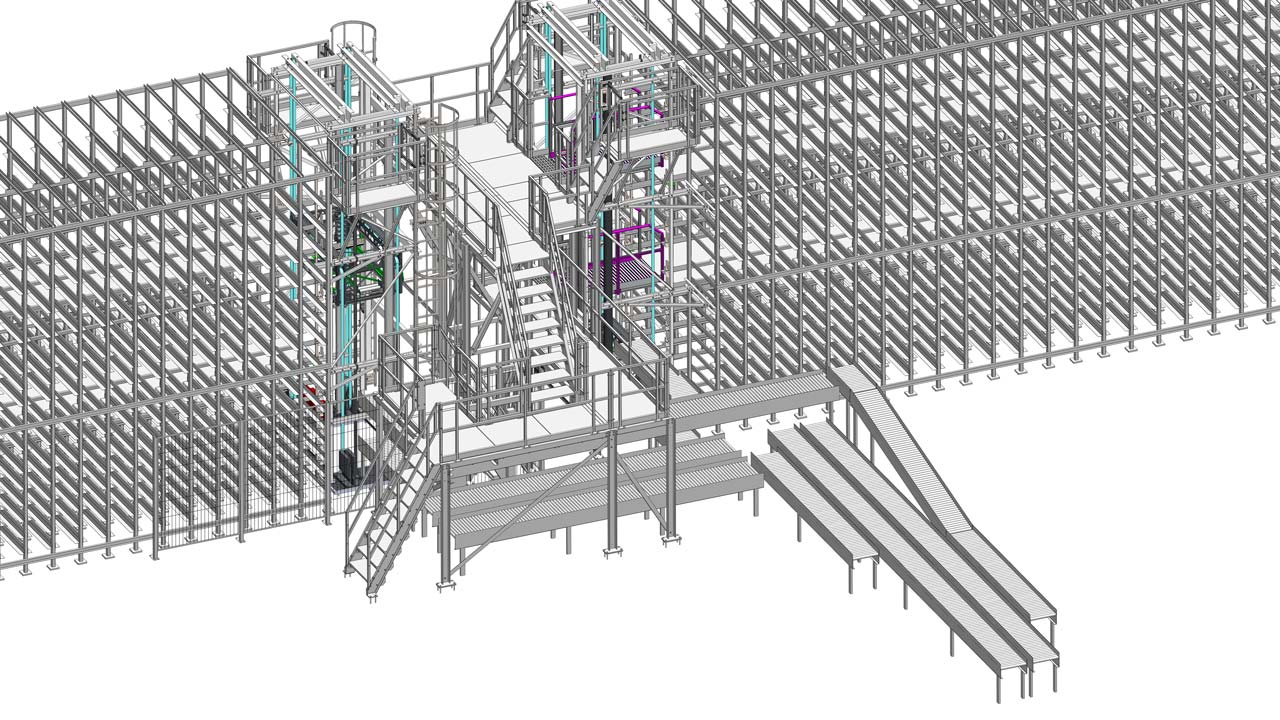

- To ensure fail-safety, the new plant is composed of two separate but interconnected areas. The distribution of goods to several storage aisles for redundant storage enables access to the required items even in the event of a system failure.

- In the event of a plant section breakdown, the uninterrupted supply of production continues to be ensured by the redundantly stored goods of the synchronised second section. This ensures that the required system safety is achieved.

- The entire system is also designed in such a way that, in an emergency, manual, hand-operated goods removal by the employees is also possible, without the need for mobile climbing aids.

- Guaranteeing the performance required to provide the goods for the production line in ongoing 2-shift operation during the entire conversion. Guaranteed by mechanical, electrical, control and software precautionary measures.

- Sequenced retrieval of the goods to be picked through optimised availability sequence thanks to the Fb Stash high-performance warehouse management software.

INCREASE IN THROUGHPUT BY > 30%

Old system: 130 double cycles (storage & retrieval) per hour.

Fb Compact Warehouse: 170 double cycles per hour.

INCREASE IN PLANT CAPACITY

Capacity old plant: 12,960 available storage locations.

Capacity Fb Compact Warehouse: 19,000 available storage locations.

WORKPLACE CONNECTIVITY

Staging zone with picking area for storage, retrieval and further processing through the production line.

Fb COMPACT SHUTTLE AS A TRANSPORT UNIT

Max. payload 120kg.

Quadruple depth storage.

Shelf-level independence for full automation beginning with the very first shuttle.

Flexible expandability for higher performance and fail-safety.

Max. speed: 2m/s. max. acceleration: 1m/s2.

VERTICAL CONVEYOR

High-performance lift for shuttle transport between rack levels.

One lift per shelving unit.

WAREHOUSE MANAGEMENT SOFTWARE

Unique software system for warehouse management, material flow control and warehouse logistics automation. Third-party integration possible for controlling entire systems with only one software.

Software level between machine control (e.g. PLC), Enterprise Resource Planning (ERP), Production Planning System (PPS) or the customer’s own Warehouse Management System (WMS).

CHRISTIAN WIELAND

Plant Planner Logistics, MAGNA STEYR Fahrzeugtechnik (Automotive) AG & Co KG

“The team from Fb Industry Automation implemented our requirements perfectly. The biggest challenge was that we had to convert and fill the new automatic small parts warehouse while it was in full operation. After integration of the first sub-system, the containers were transferred from the old system to the new system. Subsequently, the old plant was dismantled and the second part of the plant was integrated in its place”.

DOMINIK KRENN

Project Manager, Fb Industry Automation

“Thanks to the new Compact Shuttle systems from Fb, we were able to achieve a significant increase in capacity and throughput compared to the previously-used stacker crane. In addition, due to the shuttle technology used, the plant can be flexibly and cost-effectively expanded for future throughput increases.”

FURTHER CASES.

Sustainability for your intralogistics

Admittedly, change always sounds like a big challenge. But they are also opportunities for further development in a constantly changing market. But how can sustainability be implemented in your company? We show you simple ways in which we can modernize your systems and how artificial intelligence can simplify your processes.

Small, but powerful! Focus on intralogistics load carriers

Systematic coordination of staff and goods within intralogistics to make them a coherent unit comes with its fair share of challenges. Successful internal logistics requires implementation of a series of strategies and processes that make the transportation of goods within a company as efficient as possible.

Selection of the correct container system is of the utmost importance when ensuring things run smoothly. As a core element, it is the fundamental infrastructure for powerful, networked storage logistics.

Airbus trusts Fb Industry Automation with major order

For the new A321 XLR long-haul aircraft, Airbus is looking to automate production by using the innovative, flexibly scalable Fb Compact Warehouse (=automated small parts warehouse) from Fb Industry Automation. Manufacture of the rear fuselage in the new assembly hangar in Hamburg takes place with the customised automated small parts warehouse.

The Fb Compact Warehouse is flexibly scalable incl. upstream and downstream conveyor connections to incoming/outgoing goods as well as material flow control.