SMALL PARTS WORKSTATION CONNECTIONS.

Tailor-made picking and workplace design for your general conditions and requirements.

EXAMPLE OF USE

SMALL PARTS WORKSTATION CONNECTIONS.

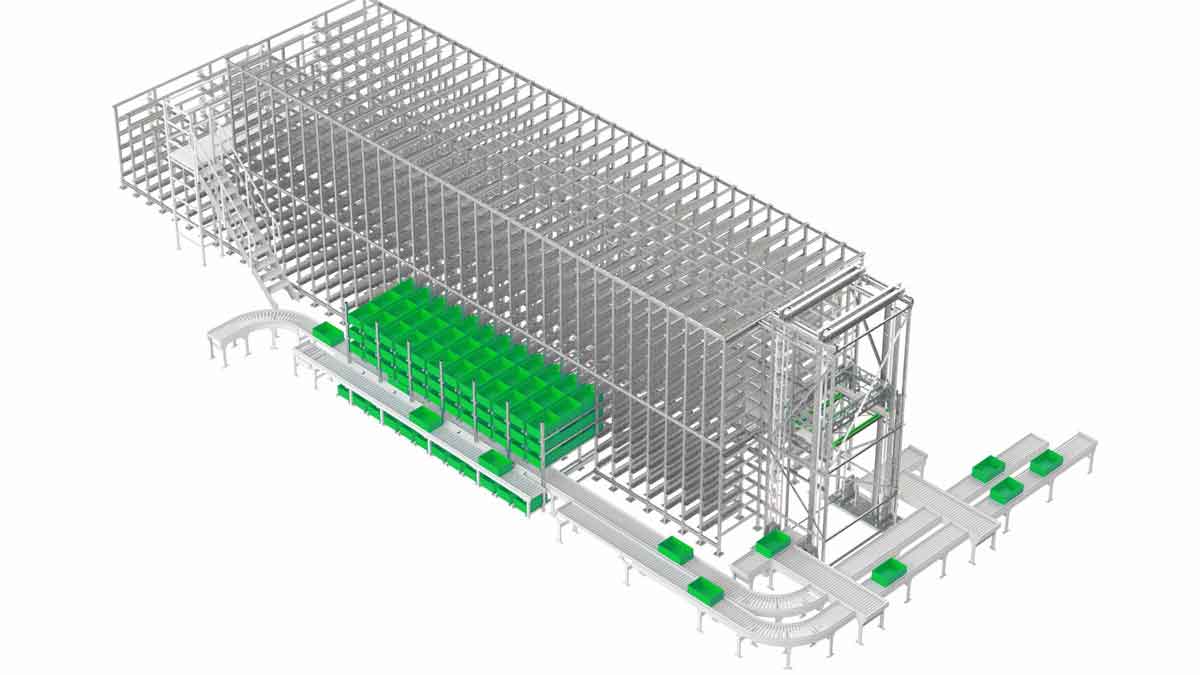

Customised small parts workstation connections are an essential element for maximum performance of an automated small parts warehouse (AS/RS). Working together with you, we adapt the picking workstations for the Fb Compact Warehouse (our AS/RS) to suit your specific needs.

CUSTOMISED ORDER PICKING FOR YOUR AUTOMATED SMALL PARTS WAREHOUSE (AS/RS).

The small parts workstation connections for your automated small parts warehouse (AS/RS), including customised picking areas, are specially designed for you and your needs. This unparalleled level of customisation optimises your employees’ work. Picking or further processing is made easier, costs are saved and efficiency is increased. This is how you achieve maximum performance. A combination of the different workstation connections is also possible in order to optimally adapt the system to your processes.

The Fb Compact Warehouse – your step into a successful future for intralogistics.

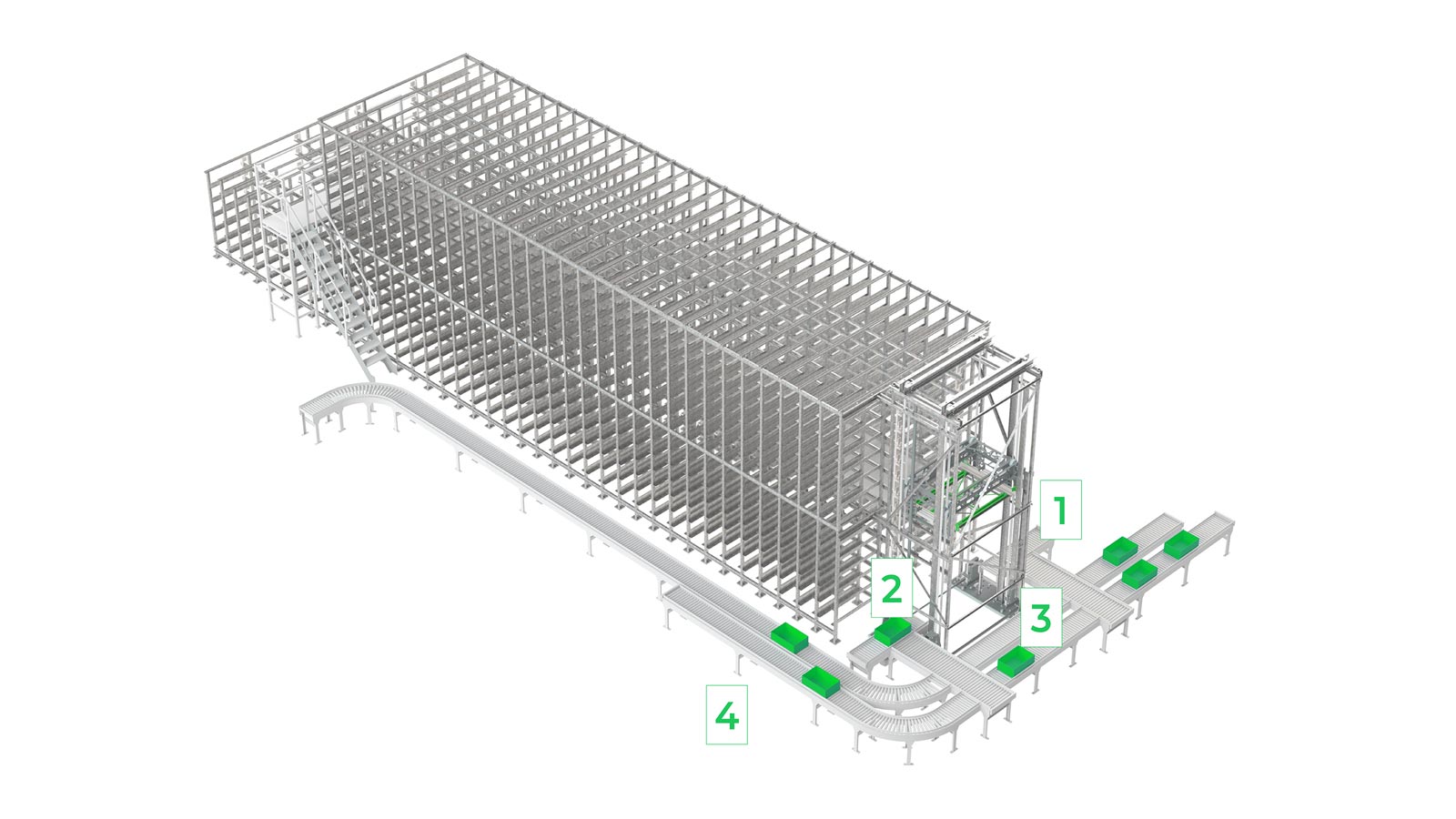

STAGING AREA WITH PICKING WORKSTATION.

High-bay warehouses can be precisely adapted to the existing local conditions, with the height of the racks ranging from around 12 to 50 metres. In combination with a multiple-depth storage system, maximum flexibility is provided in terms of the use of space. The storage, transfer and retrieval of goods in warehouse logistics is carried out in the high-bay warehouse by means of shuttles or alternatively by using storage and retrieval machines (SRMs).

When an order is initiated by Fb Stash, the necessary totes are transferred from the rack (1) by the Fb Compact Shuttles to the staging area conveyor (2) and transported via the staging area loop (3) to the picking workstation (4). The order is processed and completed there. Empty totes are removed from the system, and totes with residual material are returned to the rack via the staging area conveyor system.

ADVANTAGES

- Customised design of the staging area, adapted to your special requirements.

- State-of-the-art conveyor units.

- High throughput.

- Integration of different upstream and downstream processes.

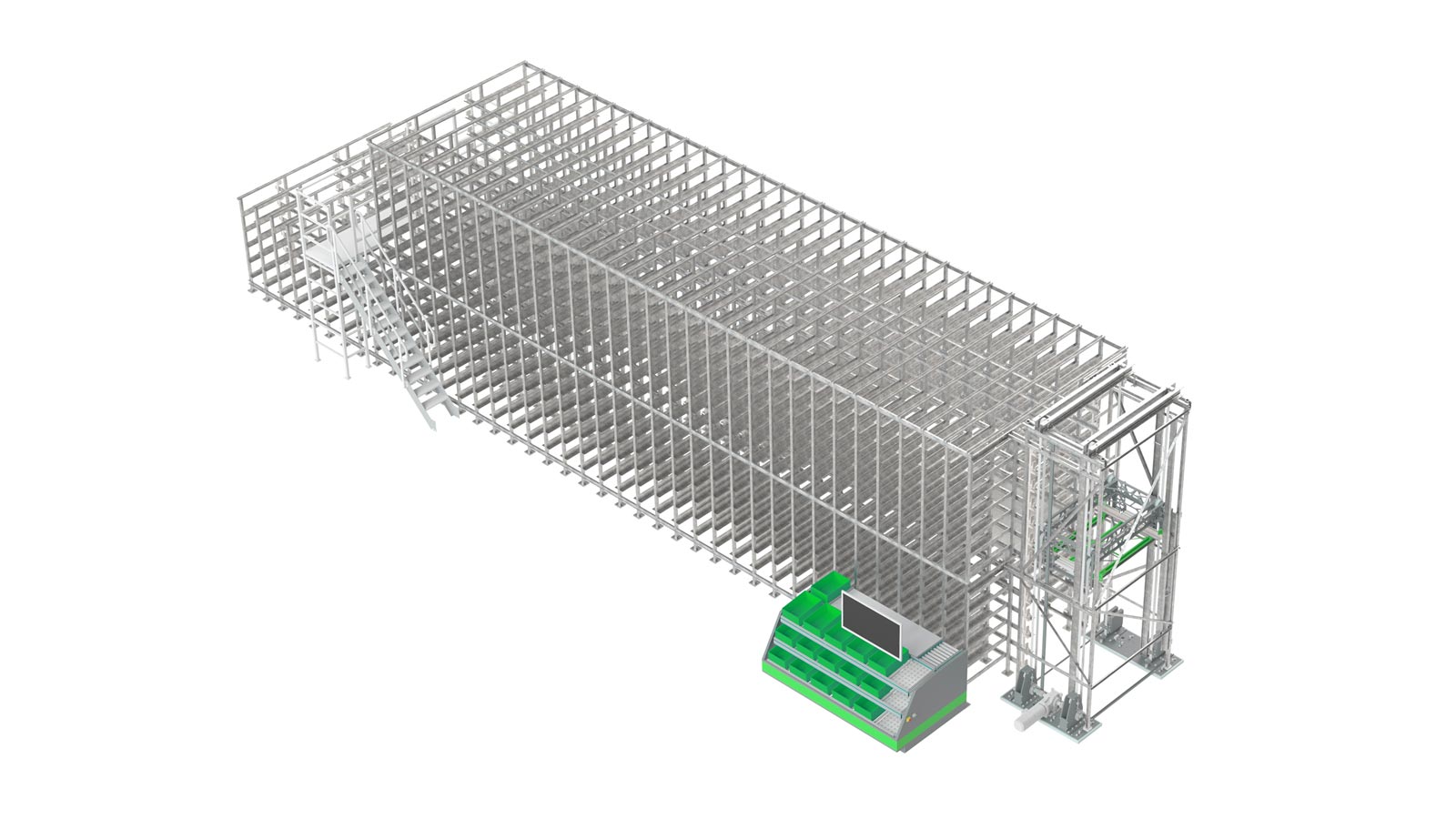

COMPACT PICK.

With the Compact Pick System, the totes are supplied without additional conveyor technology. A workstation for processing orders is integrated directly on the side of the rack. The number of Compact Pick units can be flexibly selected and expanded, as required.

The order is initiated either by the ERP system or directly on the workstation screen if it is a standalone solution. The totes with the items to be picked are transported to the upper level of the workstation (source). The order tote is made available in the lower level (target).

For order processing, the items can thus be picked easily from the source (upper level) to the target (lower level). The source totes are then returned to the system and the order totes can be used for further processing.

ADVANTAGES

- Favourable low acquisition costs due to connection optimisation.

- Low space requirement.

- Direct connection to the rack incl. Ergonomic goods-to-person (GTP) workstation design on 2 levels.

- Ergonomic goods-to-person (GTP) workstation design on 2 levels.

- Flexibly scalable — multiple picking stations along the rack possible.

- Easy handling of high tote weights.

- Direct connection to a Driverless Transport System (DTS) / Automated Guided Vehicle (AGV) possible.

FLOW RACK.

Another popular type of workstation connection are flow racks, which are attached to the side of the rack as a workstation. The order is initiated via the ERP system. Refilling of the flow racks at the workstation is done automatically by the Fb Compact Shuttles. The employee is provided with a pick-to-light system to support the picking process.

ADVANTAGES

- Fast order picking for smaller item ranges.

- Simple set-up of the workstation.

- Easy order picking through pick-to-light.

FURTHER CASES.

Hausbrot.at | Packing line | Fb Industry Automation

Hausbrot.at supplies kindergartens, businesses, and private households daily with fresh baked goods and other food products. However, with around 1,000 orders per day, the company reached the limits of its manual warehouse management. To meet the increasing demands, Hausbrot.at decided to undertake a comprehensive modernization of its intralogistics. In collaboration with Fb Industry Automation, a highly automated warehouse system was developed and implemented, which not only significantly increased efficiency but also minimized error rates and improved working conditions. Curious about how this project was realized? Discover all the details in our case study!

BIG Bundesimmobiliengesellschaft – library of the university Graz

During the realisation of the construction project “Renovation and extension” of the library of the Karl-Franzens University of Graz”, the section of the library built in the 1970s created an obstacle to this important urban development. The historic library building has been transformed over several construction phases from the original clarity of its symmetrical late-19th century layout to a complex conglomerate of different room sequences.

Library of the University Graz | Automated book conveyor system

The University of Graz (formerly Karl-Franzens University) is the largest university in Styria and the second oldest university in Austria after Vienna.

During the course of the construction project “Renovation and extension of the library of the Karl-Franzens University of Graz”, the construction of a new automated book conveyor system was also planned and implemented.